Inside Love Hunter: The Silent Rise of an American Independent Watchmaker

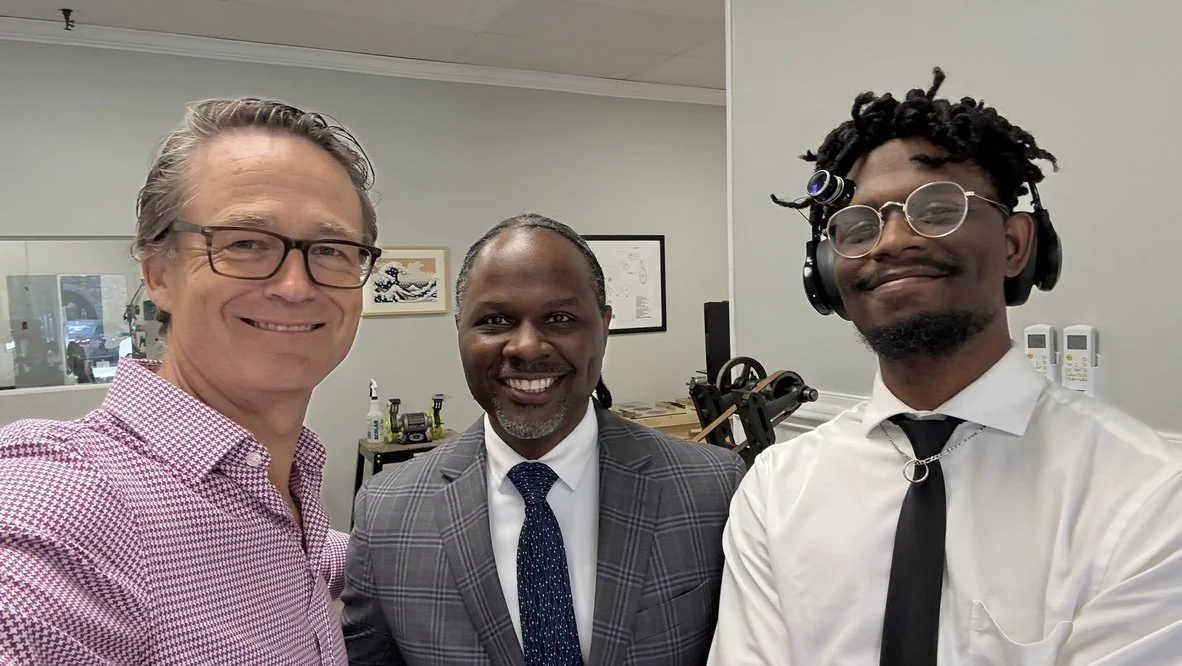

I arrived at Love Hunter Watchmaker on Thursday, August 14th. At the door, I was greeted by a gentleman in a suit and tie—a surprising and rather admirable sight. I don’t think I’ve ever been welcomed into an independent watchmaker’s atelier by someone so formally dressed. With a big smile, a firm handshake, and the words “Welcome to my place of work,” he set a tone of professionalism that immediately distinguished him from many in the artisanal watchmaking world.

The front office was immaculate—a place for meeting clients, not merely for tools and parts. From there, I was ushered through a door and into the assembly room. To my right, front and center, stood an old American watchmaker’s lathe, which Love still uses daily. Along the benches, the familiar instruments of an artisanal watchmaker were neatly laid out: files, gravers, and hand-finishing tools. I was particularly amused to see the triangular wooden dowels, each coated with varying grades of fine sandpaper, used for bevel and anglage finishing. These are supplied by Philippe Narbel’s Manufactor, which produces and distributes them to watchmakers worldwide.

Love and his son, Mick, had only just returned from Switzerland after completing an advanced hand-finishing course with Philippe Narbel himself, at his workshop in L’Abbaye.

At the back of the room stood a pair of pantograph engraving machines, used for transferring the Love Hunter logo onto dials. From there, we stepped into the back workshop—what one might call the “dirty room.” Here, rows of lathes and milling machines filled the space, each dedicated to the production of parts: wheels, dials, cases, bridges, mainplates, screws, pinions, and arbors.

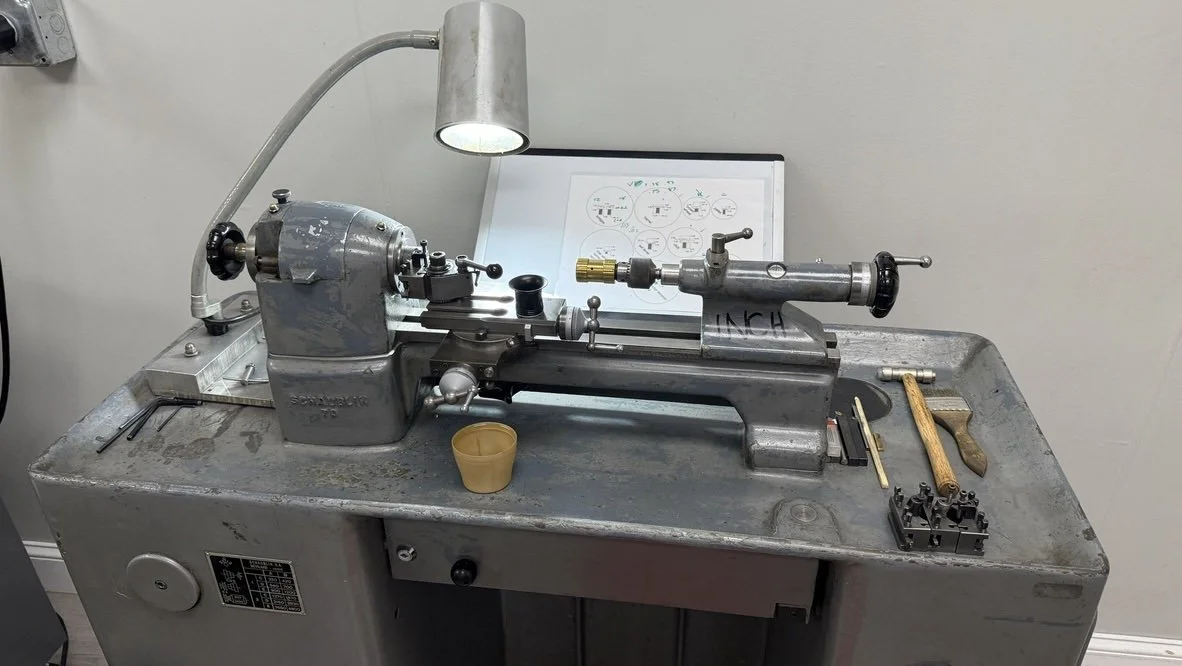

The Schaublin lathes

Two classic Schaublin lathes, a 102 and a 70, sat side by side—both clearly in daily use. On one, a set of instructions for cutting a twelve-leaf pinion was clipped to the headstock. Love explained his workflow and showed me his three-axis milling machines, which he also uses regularly. These perform operations measured in microns, essential for the precision his watches demand.

Schaublin 70 Lathe

Schaublin 102 Lathe

At one bench sat two semi-assembled prototype calibers, each representing a different execution of Love’s debut model. The first, entirely in titanium, features a titanium case, dial, mainplate, and even a titanium escape wheel bridge. The second is its 18-carat rose gold counterpart—case, dial, mainplate, and bridges all rendered in solid gold. For functional integrity, the mainspring barrel is brass, while the ratchet and crown wheels are hardened steel, their wolf’s-tooth profiles gleaming under the bench light.

Titanium escape wheels on the right.

Love explained his design philosophy and how this project—more than five years in development—has truly been a labor of love. I wasn’t permitted to take photographs; confidentiality is paramount, and he cannot risk premature exposure before the official prototype reveal. Still, he allowed me a look at a parts tray filled with brass wheels, steel pinions, and various components in different stages of finish. Even in these unfinished forms, the precision and consistency were striking.

One of the most fascinating aspects of Love Hunter’s work is his intentional absence from social media. He maintains no website, no public marketing presence whatsoever. He chooses to work in silence, away from the noise of the industry—believing that solitude protects the purity of his ideas and designs.

Lovell and Mick in the atelier.

Back in the assembly room, I saw where Mick worked, meticulously bevelling the spokes of a wheel under high magnification. This is delicate, time-consuming work that requires tremendous concentration. Here was the true test of Narbel’s teaching—and Mick, it seems, has absorbed it naturally. His patience, focus, and control suggest the hand of someone with fifteen years of experience, not a recent apprentice.

Mick’s work bench

Close up of a Wheel receiving spoke bevels

It is deeply impressive to witness this level of craftsmanship within a small father-and-son workshop in the United States, a country without the centuries-old infrastructure that supports Swiss haute horlogerie. Yet within these modest walls, artistry, precision, and mechanical poetry are alive and well.

As I left, Love thanked me for visiting and smiled quietly when I asked about the upcoming debut. In October, he will unveil his first watch to the public in New York City. After seeing what I saw—the dedication, the skill, the philosophy behind it all—I can say with confidence: Love Hunter is a name to remember.