I have known Nicolas Delaloye since 2006 when I met him in Baselworld as he exhibited with the AHCI in their stand. We connected and as I admired his watches back then, I realized here was another of these artisanal Independent Watchmakers that I could work with, bring their work to the SF Bay Area collectors in Redwood City in Silicon Valley and help promote him in the USA. The following year at the event I held at my store, Watch History in the Making II, Nicolas and his brother Christophe traveled from Geneva to share in our second annual Independent Watchmaker weekend in 2007. He brought his brother to aid in translating, as back then Nicolas did not speak English very well. His brother, an airline pilot in Switzerland, was fluent and helped enormously during that event. His work was very well received and we took several orders for his Montres Delaloye “Le Garde-Temps” model back then.

An early WG cased guillloche/MOP dial Le Garde-Temps model.

The older execution of the ND01 caliber within a WG case.

Fast forward to two years ago, when Nicolas reached out to say, he was ressurecting his watchmaking business, after spending 14 years at the Patek Philippe museum heading up their restoration department. I was eager to help again, and we began talking and met in early 2024 in Geneva to plan. His new watch, named the Renaissance, was what I was excited to hear about and earlier this year, Nicolas kindly sent the prototype to show to clients. The Tantalum 39mm case with the enamel dial in ivory or black was right up my alley in terms of design. He uses his ND01 manual wind caliber from the original series of watches. It has been up-graded and the hand finishing improved and the style arguably better. The rose gold plating on the barrel and wheel train bridges with the lovely Geneva stripes makes for a lovely contrast against the perlage rhodium plated surface of the mainplate below. Black polishing of the steel regulator and escape wheel cap in the tradition of classic Genevan watchmaking.

A quick snap of the caliber in my SF office under poor lighting conditions of the prototype tantalum Renaisssance

The prototype with ivory enamel dial in the bright California sunshine!

I took the train into Geneva main station on Tuesday morning prior to teh oipening of the AHCI show at the Ice Bergues space in the heart of Geneva. I then jumped on a tram to get out into the outskirts of Geneva to Carouge where Nicolas has his atelier on the edge of Plan-Les-Ouates. This is the industrial region on the south western edge of Geneva, where many big brands based in Geneva have their head office manufactures. Patek and Vacheron being the main two!

I was greeted at the tram stop by Christophe, Nicolas’ brother, who helps with translation on occasions, as Nicolas’ spoken English is not his strong suit. Christophe is an airline pilot, so has to be fluent in my mother tongue. We proceeded to Nicolas’ atelier, a short walk and I get to see for the first time, where his creativity and execution takes place.

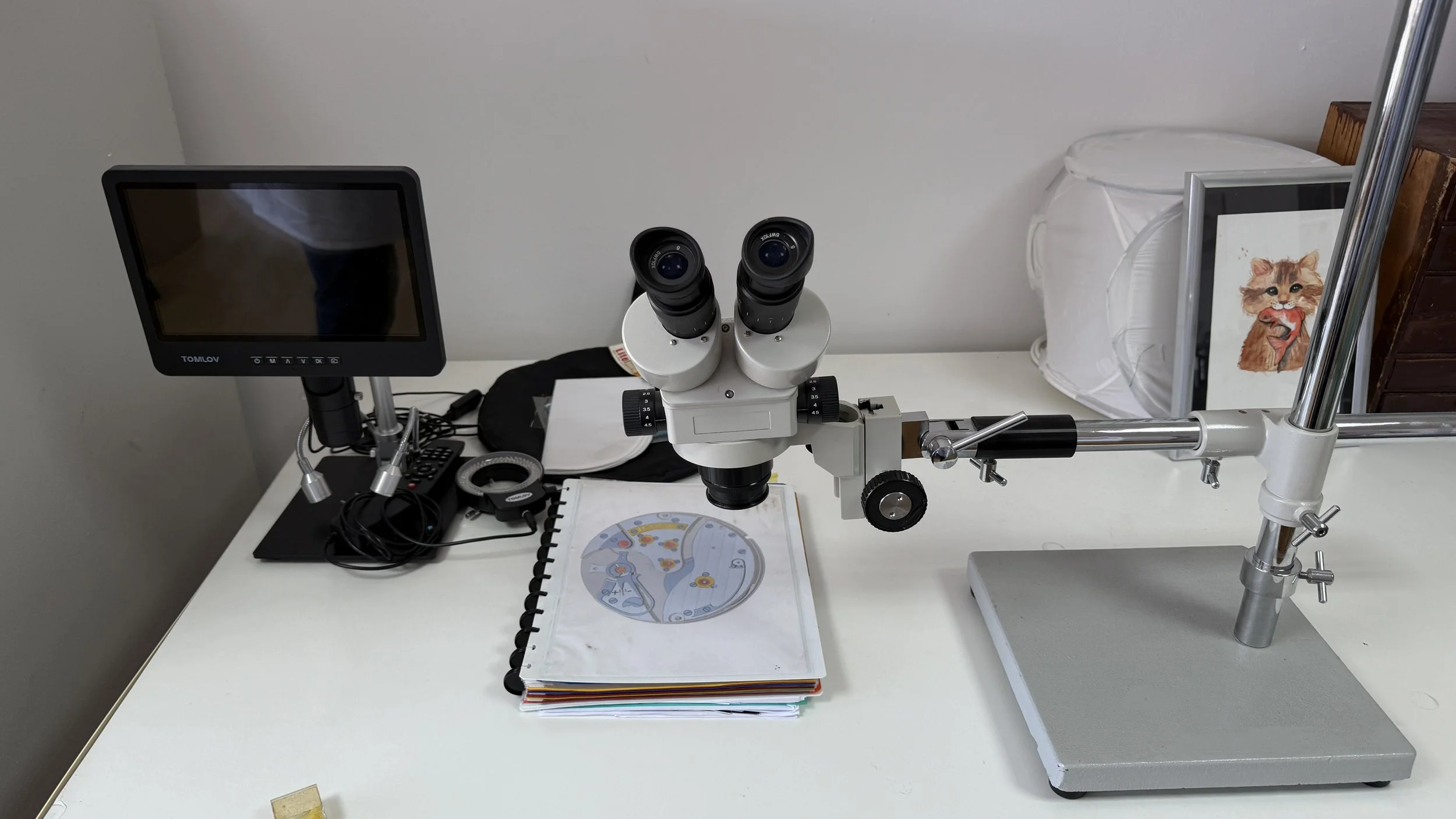

Modest accomodations in an industrial building. An office, with a table, a microscope and an old tool. The other wall a bookcase with and then into the well lit workshop, with many of the familiar traditional artisanal watchmaker tools of the trade.

An ancient wheel tooth cutter, with the huge brass index disc.

We enter to see this, in prime position was the Schaublin 70 lathe. These precision watchmaking lathes are required for the making of parts.

The atelier of Nicolas Delaloye in Geneva.

The Schaublin 70 is used almost daily by Nicolas. He demonstrated a couple of tasks while I was there.

Another Schaublin 70 lathe painted green in the back.

Here I believe the Perlage is administered to parts.

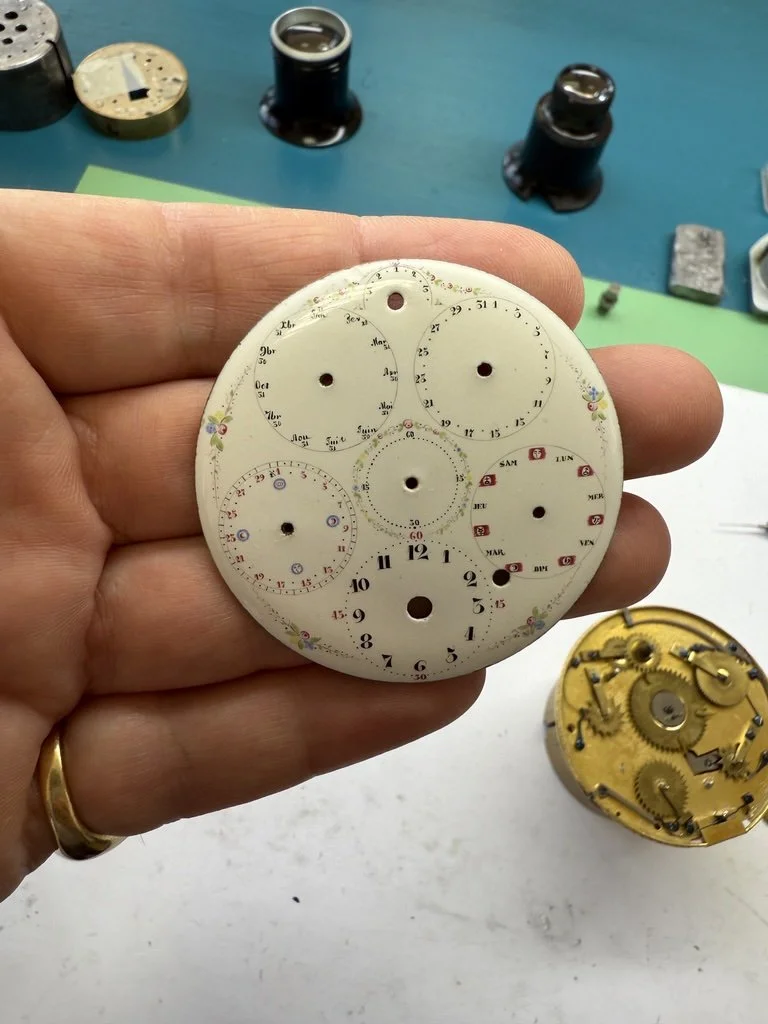

His bench contained several very old pocketwatch restorations being worked on for client’s who value his deep knowledge and expertise when it comes to being able to get their precious objects working correctly. If parts are worn, Nicolas can make a replacement so that these little machines can once more run again the way they were intended.

Three very old pocketwatches and one slightly less old, but still 100 years approx., Vacheron & Constantin piece.

This piece definitely needs some TLC by Nicolas, visible here are some worn parts, misshapen and missing teeth!

However, the enamel dial is spectacular with the flowers on the perimeter and around the center seconds dial!

Back of the enamel dial with enamel applied in order to prevent warping during the original firing.

The beautiful V&C caliber that powers the rare Inline Day, Date & Month calendar

The dial side of the Vacheron & Constantin with the bezel & crystal removed.

Nicolas then demonstrated the way he polishes certain steel parts on the Schaublin 70 including a tiny steel pivot. Then we discussed the recent Renaissance model, with him showing me parts trays for his ND01 caliber (see image below). He has his case made by a specialist casemaker in Tantalum to his specifications.

Tantalum case of the Renaissance, side view.

The enamel dial is also made by a friend in the Geneva canton. Nicolas gets to do the fine hand finishing work on his movement, where he applies the geneva stripes, the anglage and makes the black polished steel swans neck regulator and escape wheel cap. These steel parts he cuts out with a jewelers saw from raw flat steel stock and hand files to the final shape with tempering of the steel and hardening it along the way. The hand applied black polish and anglage to these parts is impressive.

Raw steel stock and a couple of parts he makes by hand.

Close up of the steel fine regulator spring prior to black polishing.

Steel click spring

He also makes his own hand sets, again, starting with a sheet of raw steel, where the rough outline of a hand is cut out with a jewelers saw and then the final shape of the hand being made is created with hand files and then very fine grit sandpapers progressively finer as one gets to the final shape and desired surface textures. As I reflect during this moment, I’m not sure I know of other artisanal Independent Watchmakers who make their own hands from scratch??? A good reminder of the background and years of skills Nicolas has acquired throughout his career in Geneva.

Steel hands roughed out prior to shaping with files.

Some blued steel hands as testers.

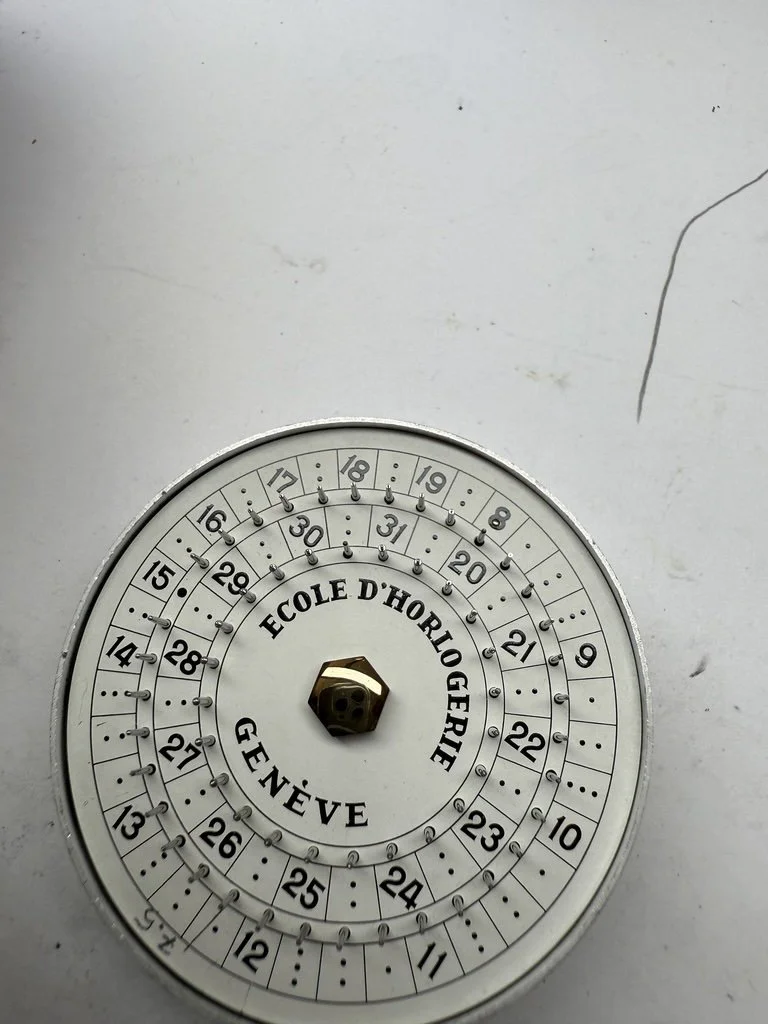

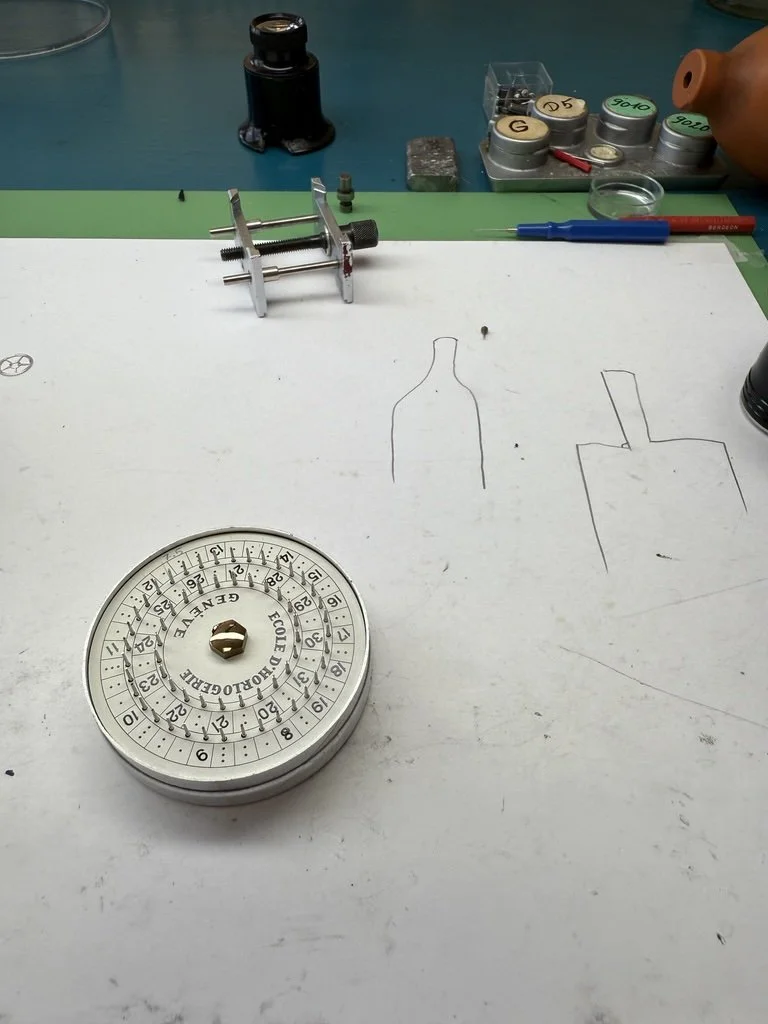

I was interested to see a disc containing a large series of pivots arranged in size order. This had “Ecole D’Horlogerie Genève” written on it, and I asked what that was for. Nicolas answered that this was part of the curriculum of the Watchmaking school he attended in Geneva. As a student, one was tested on their ability and required to complete this set accurately making all the exact sizes. Nicolas’ old micrometer was on standby to check! The “15” diameter pivot was dead nuts on I’m happy to report.

Here Nicolas was showing the outline in profile of what the school expects from their students in order to pass the requirements. Exact right angles, nothing less is acceptable.

15/100 mm

I think it worth mentioning here, that the usual watch company sponsored schooling received by many watchmakers today is often different in terms of the required skills to complete the course and emerge with a watchmaker certificate of 20 years ago. Of course it depends upon which school one attends and I suspect the curriculums have evolved somewhat to reflect the changing way watches are typically built today and also serviced within after sales departments and independent watch service businesses. However, I stand by my belief that an independent artisanal watchmaker should as part of their own education, require themselves to do several years of high end watch restoration, where the study and observation of the great watchmakers and their designs and material uses, give one a huge body of knowledge with which to go about designing and ultimately building one’s own caliber and watch. The CAD programs enable relatively quick design and prototyping of new calibers, however to my mind watches are built to last several generations with regular routine servicing. These are not “throw away” items, like much of what is consumed today by the buying public. Anyway, I digress, back to Nicolas and his amazing work in Geneva!

ND01 mainplates and barrel bridges

Pivots, pinions, screws, cams and arbors for his watches. This is a very valuable parts tray!

Nicolas’ main work bench where he creates his horological magic.

We then spent a good hour dining at a local restaurant on Place de Rondeau in Carouge a 5 minute walk from Nicolas’ atelier on a local hearty stew. We discussed the progress and plans for the future of his watchmaking and talked about plans for a US trip in due course. We then said our goodbyes, as I was headed in to the center of town to attend the AHCI event at the Ice Bergues event hall and meet up with Nicolas’ colleagues who were exhibiting there. Nicolas himself was also heading there to display his prototype to eager attendees. As with all these onsight visits to artisanal Independent Watchmaker workshop/ateliers, one comes away with a new found appreciation and a better understanding of the watchmaker and his watches. I’m thrilled as always to be able to bring you along with these articles and images, so hopefully you can get a taste of their work.

Thank you Nicolas for your kind hospitality!